Maintaining Pipe Casing Integrity

Because gas or oil pipelines tend to be buried in soil or immersed in water, they are prone to corrosion. As such, statutes 192.467 and 195.575 from the United States Department of Transportation (USDOT) state, “Buried or submerged pipelines must be electrically isolated from other underground metallic structures, unless the pipeline and the other structures are electrically interconnected and cathodically protected as a single unit.”

While this cathodic protection mitigates corrosion damage, many elements can change throughout a pipeline’s lifetime that could render this protection ineffective.

Movement

Movement

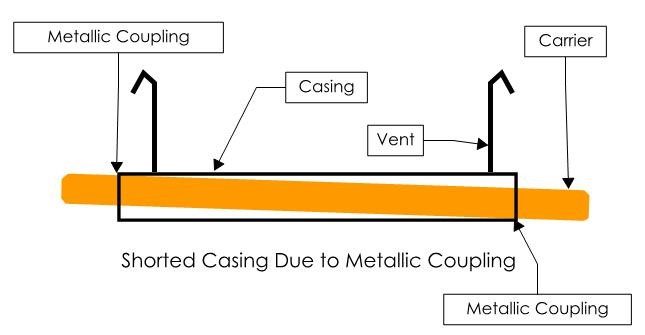

Over time, the pipeline’s casing and carrier pipe are subject to movement. And with that, you risk the casing and the carrier pipe contacting one another, also known as a metallic coupling. This could cause an interference or a “shorting” that compromises the cathodic protection.

Moisture Intrusion

Casings also risk moisture intrusion. The endings may not be properly sealed, or you may have a broken vent pipe. The excess moisture could bond the carrier pipe to the casing and cause electrolytic coupling, again shorting the cathodic protection.

Either way, you’ve got a hazard on your hands, and the USDOT requires you to fix it within six months of identification. But wait, there’s more!

Changing Topography

Gas or oil pipelines tend to be cased under roadways or railway lines. Many have been in use for 20 to 50 years. Over that time, surface topography has changed, and the location of underground casings may no longer align with the roadway or railway it originally traversed. And record data, if it even exists, is unlikely to be reliable.

So, how do you go about locating these pipe casing ends and remediating the issue?

Step One: Permitting

First, a pipeline owner or operator will contact us about a potential shorted casing. We then visit the location to analyze site specific characteristics and determine what is needed to identify the exact locale of the casing ends. Since pipelines tend to be near roadways and rail lines, this typically requires a substantial amount of permitting. So, we’ll work with the state DOT, city or county, and in some cases, all three. Once the permit is approved and issued, it’s time to get to work!

Step Two: Specialized Tools

Using geophysical tools, like electromagnetic (EM) instruments and ground penetrating radar (GPR), we can approximate where the casing ends are located by reading the frequencies. Then, we utilize vacuum excavation to expose and pinpoint the casing end.

With the ends identified, we map them using survey grade equipment so anyone with this information can easily locate them in the future. To make it even more accessible, we add a marker ball when we’re backfilling the location. Then, we create a temporary core patch using materials based on the surrounding area: Cold Patch for asphalt, Utilibond for concrete, etc.

Step Three: The Right Partner

The next step is to work with a qualified contractor to repair or remediate the issue. With the precise location of the pipe casing ends, they can excavate

what is necessary and fix the problem. If a pipeline happens to be in a high traffic area, they’ll even install a testing station in a safer spot. Once repairs are complete, they’ll backfill it and install a permanent patch.

Step Four: Deliverables

The last step is to survey the locations of the new vents and test stations. We can then create CAD files, KMZ files for Google Earth, or shape files for an internal GIS system. We bundle them all up with the test reports and send them off to our client.

The traditional method would have you in a backhoe performing costly excavation. But our process is safe, repeatable and cost-effective! Want more information or a private presentation on this topic? Contact Greg Jeffries at greg.jeffries@colliersengineering.com.

Webinar Series

This article is part of our Webinar Blog Series. We turned directly to the experts who were excited to share their latest technologies, insights and strategies. If you have questions or would be interested in a Lunch and Learn about any of the topics covered, feel free to reach out to our presenters!

Comments are closed.